Fire prevention measures are included in both the paint spray booth design and the process flow.

Paint booth fire suppression system requirements.

Nfpa and osha codes as the best method of reducing the chance of fire or explosion in your spray paint booth.

Posted on september 11.

As a manufacturer of paint spray booths the codes are very important to us and everything we do to create the safest work environment for our customer that is possible.

Aside from these minimum requirements for paint booths there are some essential safety practices to make sure your booth is maintained properly.

Restrict access for anyone with asthma allergies and respiratory illnesses.

Although nfpa 33 addresses safety through fire regulation the standard alone does not meet all the requirements for a safe paint booth environment.

Nfpa 33 9 1 1 also addresses fire suppression systems and suggests standards that different classes of fire suppression systems have to meet to be satisfactory for paint booths.

Assume the paint is conveyed to the booth through a fixed pressurized delivery system.

Requirements for fire suppression in paint booth.

Assume the paint supply is stored in a separate enclosed room that is adjacent to the booth and which shares a common concrete block wall with the booth and which is inside the same building as the booth.

Additionally osha 1910 107 f 1 is an important standard that applies to paint booth fire suppression requirements.

Governmental agencies or third party groups like the national fire protection association nfpa or underwriter s laboratories ul create administer and enforce the codes.

The key take away from these articles is that fire.

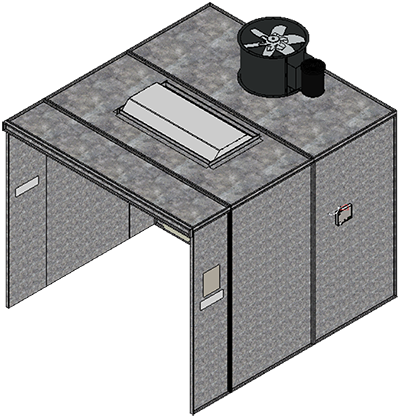

All of tools usa s spray booths are designed to comply with the nfpa 33 requirement for an after market fire suppression system that.

Spray booth safety tips.